The BMW F10 5 Series is mechanically strong, but long-term reliability depends on addressing known weak points like trunk water ingress, diesel timing chain wear, cooling system plastics, and aging electronic modules. These are predictable, preventable failures. Owners who fix them early enjoy one of BMW’s most rewarding long-term executive sedans.

Vehicle Scope and Technical Context

Short answer: This guide focuses on failure-prone systems, not cosmetic complaints.

- Platform: BMW 5 Series

- Production years covered: 2010–2017

- Engines discussed:

- Diesel: N47, N57

- Petrol: N20, N52, N55

- Drivetrain layouts: RWD and xDrive

- Data sources:

- Independent BMW specialists

- Owner teardown reports

- Workshop fault histories

- Recall documentation

Vehicle Problem Statement

Short answer: Most F10 failures originate from sealing, plastics, and service interval assumptions.

Technical clarification

The F10 introduced extensive underbody electronics, rear-mounted power distribution, electric steering, and aggressive lightweight plastic use. These systems work well when dry, cool, and serviced frequently. Heat, moisture, and extended oil intervals expose their weaknesses.

Practical outcome

A maintained F10 is reliable. A neglected one becomes electrically unstable.

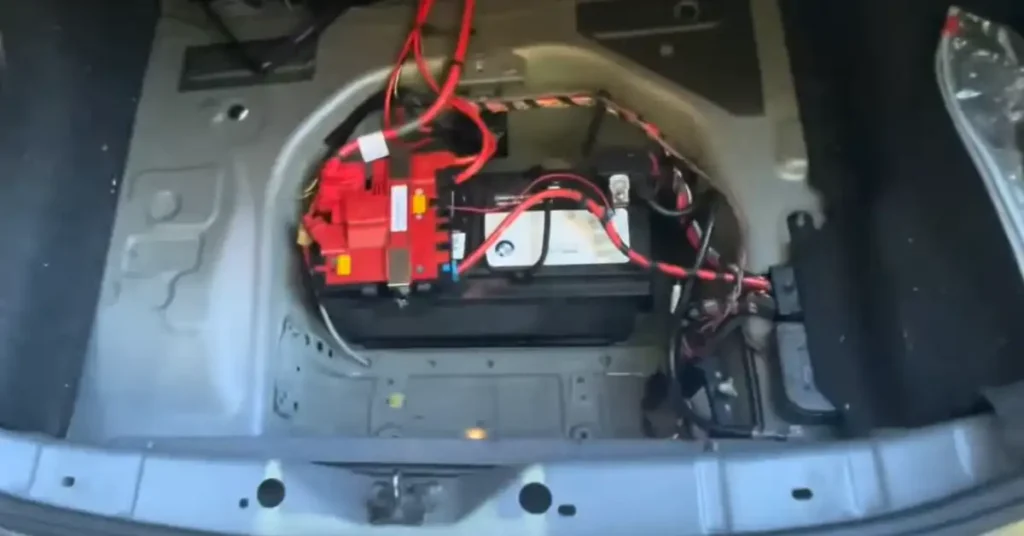

Trunk Water Ingress and Rear Electronics Failure

Battery Distribution Box

Short answer: Water in the boot can immobilize the car.

The F10’s rear boot sealing allows water to bypass the drain channel and collect in the battery well. This area houses multiple control units. Even slow moisture accumulation causes corrosion, voltage drop, and sudden non-start conditions.

Affected components (technical list)

- AGM battery

- Intelligent Battery Sensor (IBS)

- Fuel Pump Control Module (EKPS)

- Parking Distance Control (PDC) module

- Rear Electronic Power Distribution Block

- Steering angle sensor wiring junctions

Root cause

- Failed trunk grommet seal

- Degraded body seam sealant

- Blocked rear drain channels

Symptoms

- No-crank or no-start

- Random CAN bus faults

- Battery discharge warnings

- Damp boot lining or corrosion smell

Correct fix

- Replace or reseal trunk grommet

- Pressure test rear drains

- Dry and inspect all rear modules

- Apply dielectric protection where needed

Crankshaft Pulley (Harmonic Balancer) Delamination

Crankshaft Pulley

Short answer: The rubber damper fails before the pulley does.

BMW uses a bonded rubber harmonic damper on the crankshaft pulley. Heat cycling causes rubber separation, leading to chirping noises and belt misalignment. If ignored, the pulley can fail catastrophically and damage auxiliary components.

Technical details

- Rubber isolator loses adhesion

- Belt tension becomes unstable

- Vibration transfers to accessories

Early warning signs

- Chirping at idle

- Belt squeal after replacement

- Visible pulley wobble

Best practice

- Replace pulley preventively

- Inspect during belt or tensioner service

Electronic Parking Brake Cable Retainer Failure

Short answer: A broken plastic clip causes driveline noise.

A failed plastic bracket allows the electronic parking brake cable to strike the propeller shaft. This produces clunking noises often misdiagnosed as suspension or differential failure, leading to unnecessary repairs.

Components involved

- EPB cable

- Plastic underbody retainer

- Propeller shaft

Fix

- Replace retainer or secure cable

- Simple underbody repair

Sunroof Drain System Blockage

Short answer: Blocked drains redirect water into the cabin.

Debris clogs the sunroof drain channels, forcing water into headliners, A-pillars, and footwells. Left unchecked, this leads to mold, airbag sensor faults, and body control module corrosion.

Affected areas

- Headliner

- A-pillar wiring looms

- Floor body control modules

Solution

- Clear drains with compressed air

- Dry interior completely

- Preventive cleaning every service cycle

Door Vapour Barrier and Butyl Seal Failure

Short answer: Water enters through the door, not the window.

The vapour barrier behind the door card prevents rainwater from entering the cabin. As butyl adhesive ages, water bypasses the barrier and soaks carpets, leading to electrical and corrosion issues.

Symptoms

- Wet carpets

- Fogging windows

- Electrical glitches in footwell modules

Correct repair

- Remove door card

- Reseal barrier with fresh butyl tape

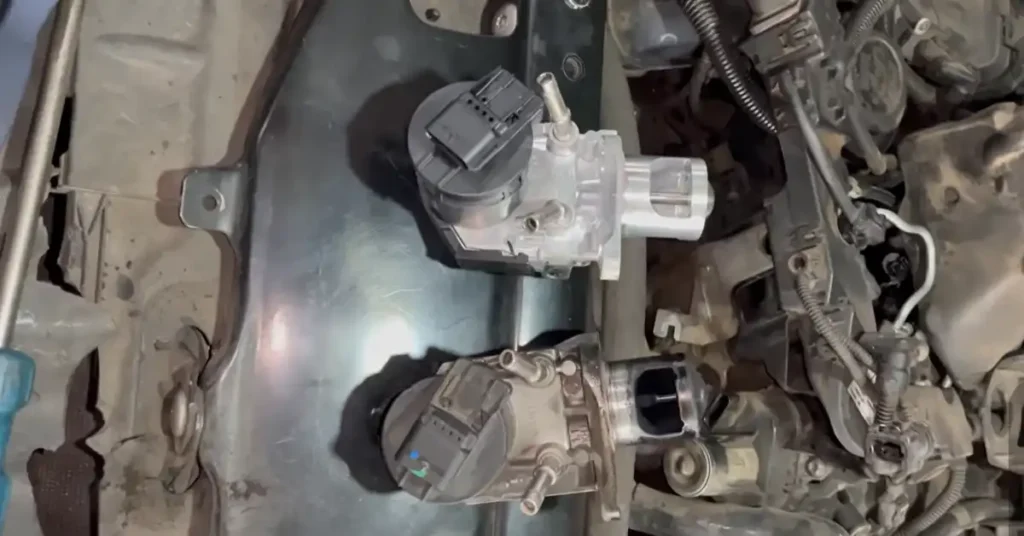

Diesel EGR, Intake Manifold, and Throttle Body Carbon Buildup

Diesel EGR (Exhaust Gas Recirculation) Valve

Short answer: City driving accelerates soot accumulation.

Diesel F10s develop heavy carbon buildup in the EGR valve, intake manifold, swirl flaps, and throttle body. This is usage-related, not a defect, and becomes significant beyond 100,000 km.

Components affected

- EGR valve

- EGR cooler

- Intake manifold

- Swirl flap assemblies

- Throttle body

Symptoms

- Reduced torque

- Limp mode

- Excessive smoke

- Check engine light

Maintenance strategy

- Periodic intake cleaning

- Longer highway runs

- Budget for cleaning, not failure

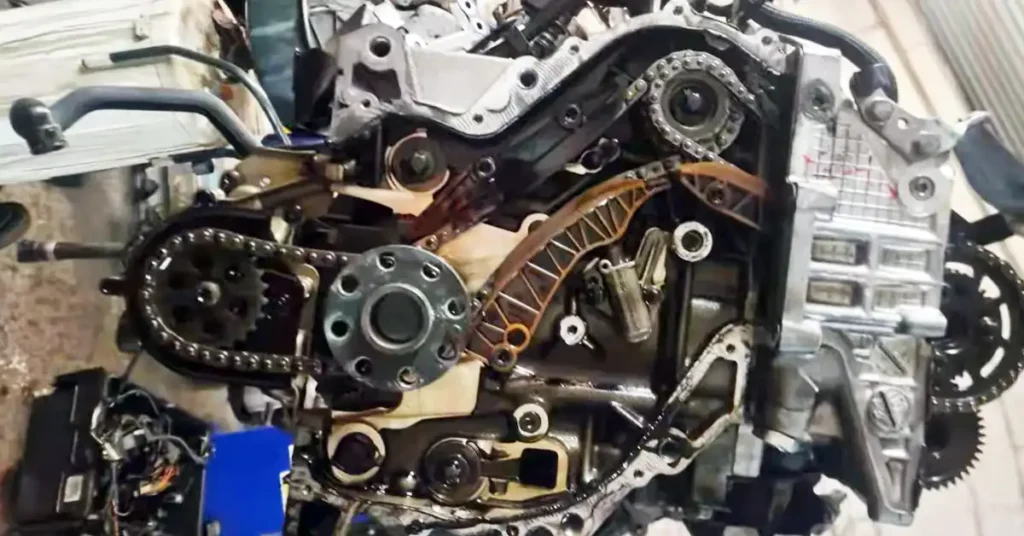

Timing Chain Wear on Diesel Engines

BMW N47 N57 Timing Chain Assembly

Short answer: Oil service intervals determine chain life.

The N47 diesel timing chain relies on oil-fed tensioners with narrow jets. Extended oil intervals cause jet clogging, leading to chain stretch and guide wear. Failure is expensive but preventable.

Warning signs

- Rattling on cold start

- Drivetrain warnings

- Metallic noise from rear of engine

Preventive approach

- Oil changes every 8,000 km

- Replace chain proactively if history is unclear

Cooling System Weak Points

Coolant Expansion Tank

Short answer: Plastic cooling parts age poorly.

Common failure points

- Electric water pump

- Thermostat housing

- Expansion tank

- Upper and lower radiator hoses

- Plastic hose connectors near heat management module

Symptoms

- Coolant loss

- Overheating warnings

- Sweet smell from engine bay

Best practice

- Pressure test system

- Replace plastics preventively after 100,000 km

Quick Diagnostic Reference Table

| Symptom | Likely Cause | Technical Action |

| No start, wet boot | EKPS shorted | Reseal trunk, replace module |

| Chirping noise | Crank pulley delamination | Replace harmonic balancer |

| Wet carpets | Vapour barrier failure | Reseal with butyl |

| Limp mode diesel | EGR clogging | Intake system cleaning |

OBD-II Fault Code Cheat Sheet

| Code | Meaning | Root Cause |

| P0401 | EGR insufficient flow | Carbon buildup |

| P0016 | Timing correlation | Chain stretch |

| P0128 | Coolant temp low | Thermostat failure |

| P2187 | Lean condition | Intake leak |

Safest Years vs Years to Approach Carefully

Safest choices

- 2015–2017 petrol F10

- Cars with documented oil intervals under 10,000 km

Higher risk

- 2010–2014 diesel with unclear history

- Cars showing moisture-related faults

Aftermarket Conversation (Owner Reality)

Short answer: Owners who fix sealing issues early report excellent reliability.

Common owner consensus:

- Trunk sealing is mandatory

- Diesel engines last with short oil intervals

- Most electrical issues trace back to water, not electronics

FAQs

Is trunk flooding really that serious?

Yes. It can disable the fuel pump control unit instantly.

Are petrol models more reliable than diesels?

Generally yes, due to fewer emissions and timing chain risks.

Can I daily-drive an F10 long term?

Yes, with preventive maintenance and proper sealing.

Is this car DIY-friendly?

Many common fixes are simple and low-cost.

BMW F10 Reliability in Extreme Heat

High temperatures in the UAE accelerate seal degradation, coolant evaporation, and battery stress. F10 owners benefit from proactive cooling system service, frequent oil changes, and early moisture diagnostics. MotorHub connects BMW owners with workshops experienced in heat-related electrical and cooling failures, helping prevent avoidable breakdowns.