Summary

The Toyota Hilux remains one of the most durable pickup platforms globally, but modern versions introduce new reliability variables. Injector sealing, oil control, DPF management, and now 48V mild-hybrid components define long-term outcomes. This guide explains what fails, why it fails, and how to diagnose issues before damage occurs.

Is the Toyota Hilux really reliable in 2026?

Short answer: yes, but modern emissions and hybrid systems add complexity that owners must understand.

The core IMV ladder-frame platform remains mechanically robust. However, post-2020 Hilux models introduce DPF-heavy emissions control and, from 2025–2026, mild-hybrid electrical assistance. Reliability now depends as much on thermal management and diagnostic discipline as mechanical strength.

Why do some Hilux engines fail earlier than others?

Short answer: failure patterns changed from mechanical wear to emissions and thermal stress. Older failures were driven by injector sealing and oil contamination. Newer failures are more often linked to regeneration logic, pressure sensors, hybrid battery heat exposure, and short-cycle driving that prevents proper exhaust temperatures.

New for 2025–2026: 48V Mild Hybrid System Reliability

Short answer: the 48V system improves efficiency, but long-term durability in extreme heat is still being evaluated.

What changed technically

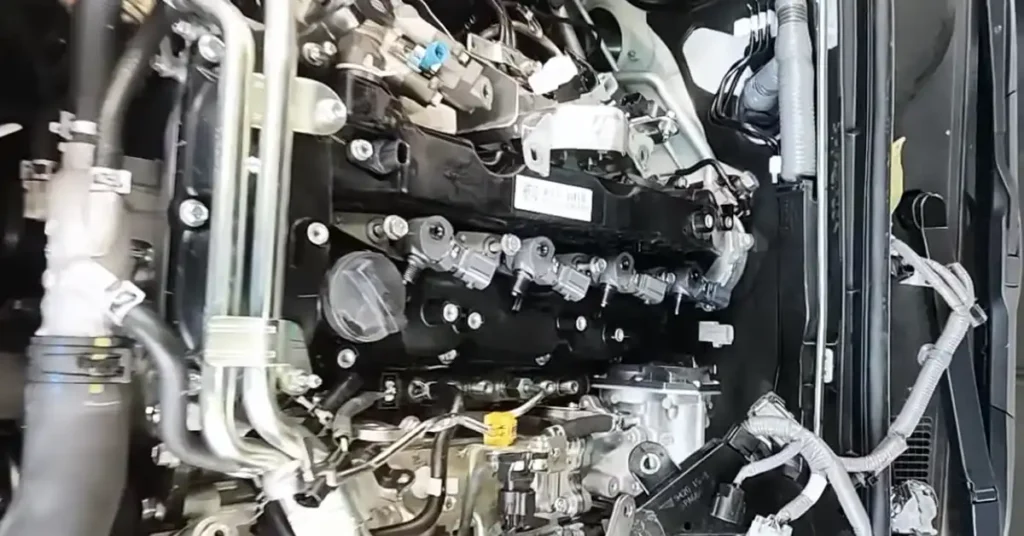

The latest Hilux introduced a 48V mild-hybrid system paired with the 2.8L 1GD-FTV engine, using:

- A belt-driven motor-generator unit (MGU)

- A 48V lithium-ion battery pack

- DC-DC converter supporting the 12V system

This system assists engine restart, low-RPM torque fill, and energy recovery under braking.

Known reliability considerations

- Battery thermal exposure: prolonged ambient temperatures above 45°C accelerate cell degradation

- DC-DC converter heat soak: reduced efficiency under sustained load

- Electrical dependency: low 48V health can trigger drivability complaints without mechanical faults

Diagnostic reality

- Hybrid warnings often do not store traditional OBD-II codes

- Voltage imbalance between 48V and 12V systems can mimic alternator failure

- Battery cooling airflow must remain unobstructed

Technician guidance

- Monitor 48V battery temperature and internal resistance

- Perform voltage stability tests during idle stop cycles

- Avoid jump-starting errors that damage the DC-DC converter

Key insight: the 48V system is not failing widely, but its behavior in desert climates is still being monitored closely by technicians.

DPF reliability in modern 2.8L (1GD-FTV) engines

Toyota Hilux DPF (Diesel Particulate Filter) system.

Short answer: most modern Hilux DPF failures are usage-related, not component defects.

Why DPF issues are increasing

The 1GD-FTV engine relies on frequent regeneration to burn accumulated soot. Short trips, light loads, and extended idling prevent exhaust temperatures from reaching regeneration thresholds.

Common failure mechanisms

- Soot loading exceeds calculated limits

- Differential pressure sensor drift

- Exhaust gas temperature sensor bias

- Failed regeneration attempts stored by ECU

Diagnostic confirmation

Technicians evaluate:

- DPF differential pressure at idle and load

- Regeneration frequency and completion history

- Pre- and post-DPF temperature delta

- Sensor plausibility compared to calculated airflow

Manual regeneration override

Professional scan tools allow forced regeneration under controlled conditions when:

- Oil dilution is within limits

- No injector or EGT faults are present

- Exhaust backpressure is below damage thresholds

Manual regeneration should never be attempted without confirming sensor accuracy.

Correct repair hierarchy

- Validate pressure and temperature sensor accuracy

- Perform forced regeneration if soot load is recoverable

- Clean DPF only if ash loading exceeds regeneration capability

- Replace DPF only after confirming substrate damage

Critical insight: replacing the DPF without correcting the root cause leads to repeat failure.

Diesel injector failures explained in depth

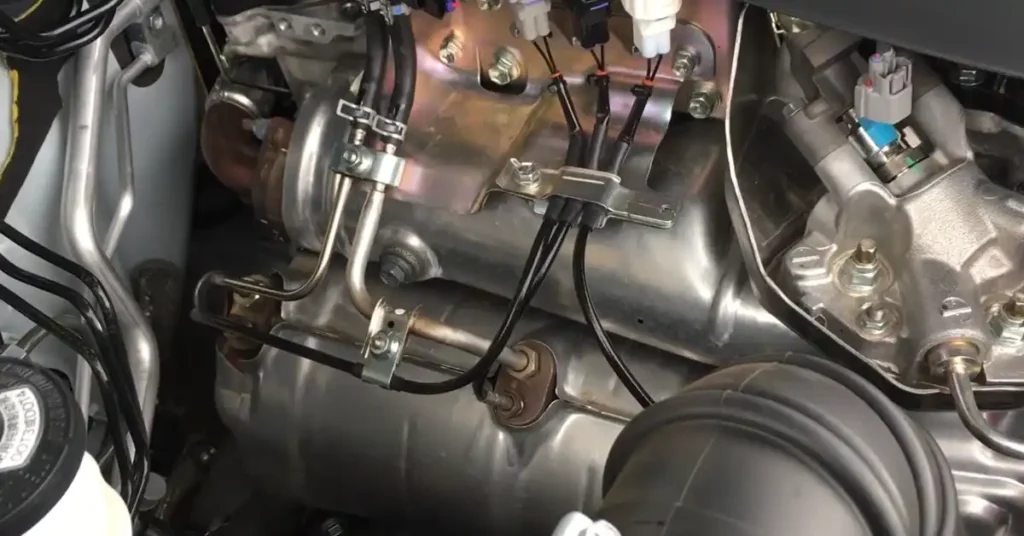

Toyota Hilux Diesel injector

Short answer: injector seal failure still matters, even on newer engines.

While Toyota revised injector sealing after early 1KD issues, improper torque, heat cycling, or skipped inspections can still allow combustion gas leakage.

Diagnostic thresholds

- Injector correction beyond ±3 mm³/stroke

- Excess return flow variance above 20 percent

- Oil level rising between services

Correct solution

- Replace injector seats and seals together

- Clean injector bores

- Re-learn injector compensation values

- Inspect sump pickup if contamination is suspected

Engine oil contamination and seizure risk

Short answer: oil starvation remains the only true engine killer.

Even in newer engines, oil thickening from soot or fuel dilution can block pickup strainers.

Prevention protocol

- Oil changes shortened under heavy duty use

- Oil analysis when injector imbalance is detected

- Visual pickup inspection if oil thickening is present

Turbocharger and stepper motor failures

Toyota Hilux turbocharger unit

Short answer: electronic control failure triggers limp mode, not turbo destruction.

Modern variable-geometry turbos depend on actuator precision.

Key diagnostic points

- Actuator sweep test before turbo replacement

- Check vane movement under commanded load

- Verify no carbon seizure in vane ring

Clutch and driveline durability under load

Short answer: torque exceeds factory clutch margin in real-world use.

Heavy towing and off-road work overwhelm standard clutch clamping force.

Correct approach

- Upgrade pressure plate and friction material

- Inspect flywheel heat spots

- Adjust driving technique during low-speed torque events

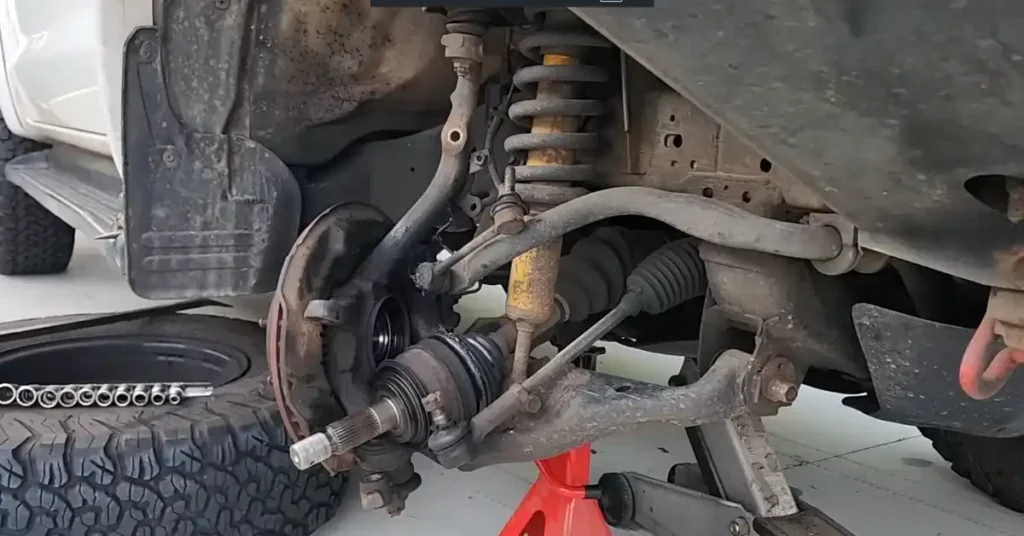

Suspension and CV joint stress

Short answer: geometry, not material quality, causes failure.

Extreme articulation and steering lock under load accelerate CV wear.

Prevention

- Inspect boots after off-road use

- Replace dampers before they overheat internally

- Align only after bushing integrity is confirmed

Electrical system reliability in modern Hilux

Short answer: voltage stability now affects drivability more than mechanical faults.

With hybrid assistance and advanced ECUs:

- Poor grounds trigger cascading faults

- Battery health directly affects throttle response

- Alternator diagnostics must include DC-DC output testing

OBD-II and system diagnostic reference

Short answer: codes identify systems, not parts.

| Code | System | Diagnostic Direction |

| P0200–P0204 | Injectors | Balance and return flow |

| P2463 | DPF pressure | Sensor or soot load |

| P2002 | DPF efficiency | Regen validation |

| P1251 | Turbo control | Actuator test |

| Hybrid system warning | 48V system | Voltage and temperature |

Best Toyota Hilux years to buy vs years to inspect closely

Short answer: later revisions are safer, but usage matters more than model year.

| Category | Model Years | Reason |

| Safest | 2018–2024 | Mature emissions systems |

| Acceptable | 2016–2017 | Revised injector sealing |

| Use caution | 2005–2007 | Early D-4D design |

| Inspect carefully | 2025–2026 | New hybrid tech, still maturing |

Final verdict

Short answer: the Hilux is still mechanically strong, but diagnostics now matter more than ever.

The modern Hilux does not break suddenly. It signals distress through pressure, temperature, voltage, and adaptation data long before damage occurs. Owners who respect regeneration cycles, thermal limits, and diagnostic warnings enjoy exceptional longevity.

Keeping your Toyota Hilux reliable in the UAE

Short answer: heat shortens every margin.

In UAE conditions, oil oxidation, injector seal hardening, DPF soot loading, and hybrid battery thermal stress all occur faster than global assumptions. MotorHub UAE works with diesel and hybrid specialists who apply desert-specific diagnostics, regeneration strategies, and voltage testing to keep Hilux ownership predictable, not reactive.