The Toyota HiAce is one of the most durable commercial vans ever built, but reliability depends on workload, heat exposure, and service discipline. Most failures develop gradually through injector seat leakage, cooling fatigue, drivetrain stress, DPF clogging, and electrical resistance. This guide explains what actually breaks, why it breaks, and how informed owners prevent costly downtime.

Is the Toyota HiAce actually reliable?

Short answer: yes, but reliability is workload-dependent, not mileage-dependent.

The HiAce regularly exceeds 300,000 km in commercial service. Failures rarely occur suddenly. Vans used in stop-start delivery, shuttle duty, or desert heat experience accelerated wear. Fleet operators catch problems early. Private owners often miss early warnings and mistake gradual failure for sudden breakdowns.

Why do some HiAce years perform better than others?

Short answer: mechanical simplicity and fuel system revisions matter more than age.

Early naturally aspirated diesels and late-cycle D-4D engines age predictably. Mid-cycle engines introduced higher injection pressures and emissions hardware before durability refinements arrived. Later years benefit from revised injector seats, improved cooling layouts, and better electrical protection.

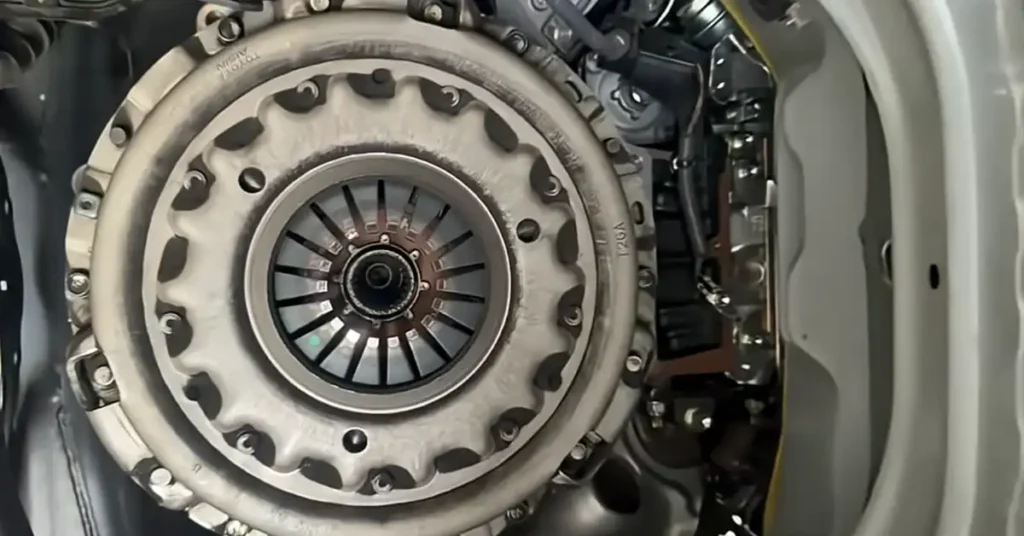

Gearbox and clutch wear in HiAce vans

Short answer: clutch and synchro wear come from load and driving pattern, not weak design.

Manual HiAce vans used for delivery or passenger service frequently report clutch slip, gear grinding, or loss of specific gears.

Technical problem statement

Repeated high-load launches overheat clutch friction material and accelerate synchro wear. Linkage cables stretch or detach under vibration, causing missed gear engagement.

Diagnostic confirmation

- Clutch slip under load

- Grinding during 2nd or 3rd gear selection

- Excessive shifter play

- Metallic debris in gearbox oil

Correct repair strategy

- Replace clutch disc, pressure plate, and release bearing as a set

- Inspect and replace linkage cables

- Drain gearbox oil and inspect for contamination

Diesel injector wear and injector seat leakage (2.5 D-4D)

Short answer: injectors cause symptoms, injector seats cause engine failure.

This is the most documented HiAce failure on Toyota forums.

Technical problem statement

Failed copper injector washers allow combustion gases into the valve cover. Carbon contaminates oil, thickens it, and blocks the oil pickup. Engines fail from oil starvation, not injector spray alone. This condition is widely known as “Black Death.”

Diagnostic confirmation

- Diesel smell in engine oil

- Rising oil level

- Black sludge under oil filler cap

- Injector “chuffing” sound

- Low hot-idle oil pressure

Correct repair strategy

- Replace injector seats with updated washers

- Mechanically clean injector bores

- Remove sump and clean oil pickup screen

- Replace injectors if return flow exceeds specification

Technician insight: topping up oil hides the failure while damage continues internally.

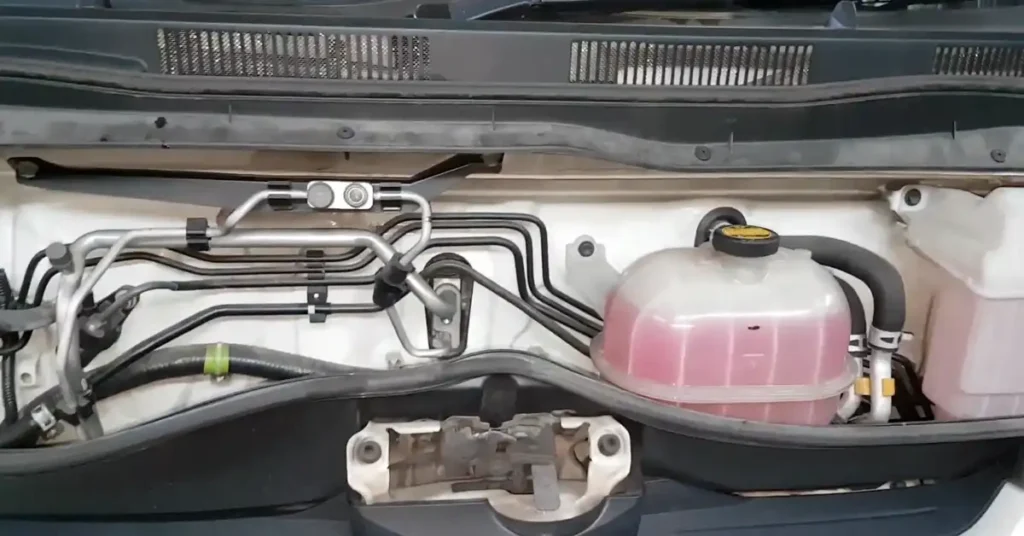

Cooling system failures (radiator and water pump)

Short answer: heat and load accelerate seal and plastic fatigue.

Radiator end-tank cracking and water pump seal failure are common in high-load or hot-climate use.

Diagnostic confirmation

- Coolant loss without hose leaks

- White residue on radiator tanks

- Overheating under load

- Weak cabin heater output

Correct repair strategy

- Replace radiator and water pump together

- Pressure test cooling system annually

- Use correct coolant specification only

EGR valve and intake carbon buildup

Short answer: short trips prevent proper exhaust cleaning.

Carbon buildup causes rough idle, black smoke, and limp mode.

Diagnostic confirmation

- Reduced throttle response

- EGR flow fault codes

- Visible intake soot

Correct repair strategy

- Remove and clean EGR valve

- Clean intake manifold if restricted

Restore driving patterns that allow regeneration

Turbocharger wear and smoke complaints

Short answer: oil starvation and dust ingestion kill turbos.

White or grey smoke on startup often precedes black smoke under load.

Diagnostic confirmation

- Oil residue in intercooler

- Excessive turbo shaft play

- Boost pressure deviation

Correct repair strategy

- Inspect oil supply and return lines

- Replace turbo if shaft wear is confirmed

- Replace air and oil filters immediately

Electrical failures and hot-start issues

Short answer: heat increases electrical resistance.

HiAce vans frequently suffer hot-start or no-crank complaints.

Diagnostic confirmation

- Cranks but will not start when hot

- Voltage drop at starter

- Intermittent electrical resets

Correct repair strategy

- Replace ignition switch or starter as needed

- Clean and reinforce ground points

- Load-test charging system

Suspension, brake, and driveline fatigue

Short answer: payload accelerates chassis wear.

Heavy use causes bushing collapse, shock degradation, brake vibration, and driveshaft centre bearing failure.

Correct repair strategy

- Replace suspension bushings and shocks as assemblies

- Inspect driveshaft centre bearing rubber isolator

- Balance driveshaft after bearing replacement

Rust and body corrosion

Short answer: neglected underbody washing causes structural rust.

Wheel arches, door sills, and underbody seams corrode first.

Preventive approach

- Annual underbody inspection

- Early rust treatment

- Regular underside washing

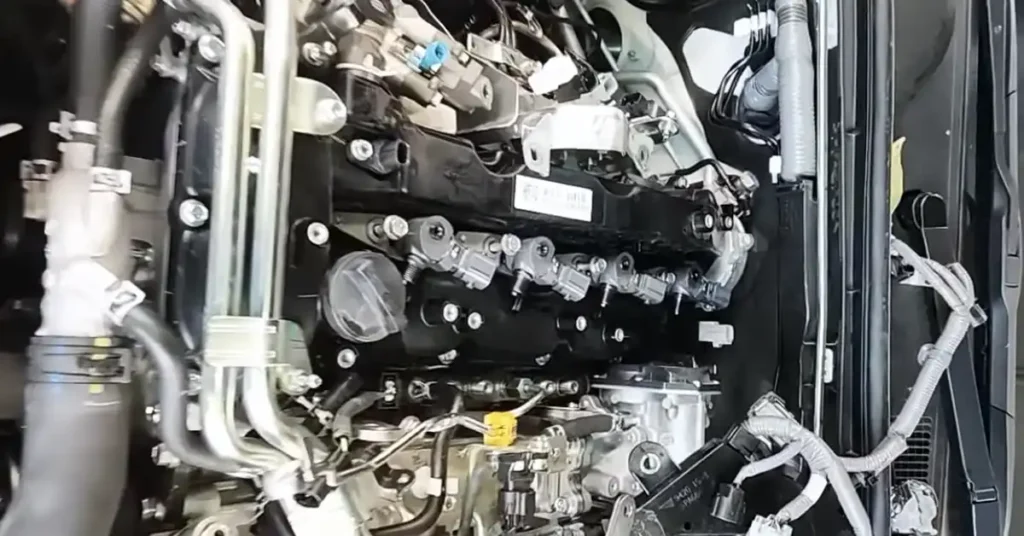

2026 Update: 300 Series HiAce and the 2.8L 1GD-FTV

Short answer: the engine is strong, emissions and software now define reliability.

From 2019 onward, the HiAce moved to the 300 Series with the 2.8L 1GD-FTV engine.

Known repeat issues

- Exhaust manifold gasket leaks

- Rear main seal seepage

- Oil dilution from failed DPF regeneration

- EGT and pressure sensor failures

Correct service approach

- Monitor oil viscosity, not just level

- Shorten oil intervals to 7,000 km in commercial UAE use

- Inspect exhaust gaskets at every service

DPF issues in 300 Series HiAce vans

Short answer: DPF clogging is now the main cause of limp mode.

How problems start

- Short trips and cold starts

- Failed passive regeneration

- Rising exhaust backpressure

Early warnings

- Flashing DPF light

- “Regeneration Required” message

- Increased idle speed

Correct diagnostic direction

- Read differential pressure values

- Review regeneration history

- Check oil dilution

- Perform manual regeneration where supported

ADAS and sensor calibration failures (2020+)

Short answer: miscalibration causes more faults than sensor failure.

Commercial use leads to frequent glass and bumper replacement.

Common causes

- Windscreen replacement without recalibration

- Bumper repairs

- Aftermarket bull bars

- Dust and sand blocking sensors

Correct fix

- Camera and radar recalibration after repairs

- Clean radar behind Toyota emblem regularly

- Avoid non-approved accessories

Electrical corrosion points specific to HiAce

Short answer: heat and sand affect starter and alternator circuits.

Common UAE failure points

- Starter relay sticking

- Alternator wiring corrosion

- Ground strap oxidation

Correct diagnostic direction

- Voltage drop testing under load

- Relay thermal resistance checks

- Ground continuity testing

Technical Check: OBD-II Fault Codes That Matter

Short answer: codes identify systems, not parts.

| Issue Area | Common Codes | Diagnostic Direction |

| Injector circuit | P0201–P0204 | Injector balance and return flow test |

| Oil pressure | P0520 | Inspect oil pickup and relief valve |

| Glow system | P0380 | Resistance test glow plugs |

| Alternator | P0620 | Load and ripple voltage test |

| EGR flow | P0401 | Inspect EGR valve and intake |

| Fuel pressure | P0087 | Check supply restriction |

| Overheating | P0217 | Cooling system pressure test |

Safest Toyota HiAce Years to Buy – 2026 Market Guide

Short answer: the best HiAce depends on whether you value mechanical simplicity or modern compliance.

| Category | Model Years | Technical Verdict |

| Safest (Elite) | 2023–2026 | Late 300 Series. DPF and ADAS software largely patched. Best choice for regulated fleets |

| Safest (Mechanical) | 2017–2018 | Late 200 Series. Peak reliability with minimal emissions complexity |

| Best Value | 2012–2015 | Strong durability if injector seat updates were performed |

| Use Caution | 2019–2021 | Early 300 Series. Higher reports of DPF limp mode and calibration issues |

| High Risk | Pre-2009 | Elevated “Black Death” risk from old-spec injector seals |

What this means for buyers and fleet operators

Short answer: the HiAce did not become less reliable, it became more technical.

In 2026, HiAce reliability is determined by diagnostics, regeneration strategy, injector sealing, and calibration discipline, not raw engine strength. Owners who understand the systems see exceptional uptime. Those who ignore warnings experience preventable failures.

What real HiAce owners report after 5–10 years

Short answer: failures warn early.

Forum data shows the same pattern: smoke ignored, oil topped up, cooling leaks dismissed.

“It never failed suddenly. I just didn’t act early.”

Final verdict

Short answer: the HiAce rewards preventive ownership.

The HiAce is not fragile. Its failures are mechanical, predictable, and gradual. Owners who diagnose early enjoy exceptional longevity. Those who delay repairs create cascading damage that gives the van an unfair reputation.

MotorHub UAE: Why HiAce Reliability Changes in Desert Conditions

Short answer: heat and dust accelerate everything.

In UAE conditions, oil oxidizes faster, cooling plastics fatigue earlier, and electrical resistance rises sooner than global schedules assume.

UAE-adjusted service guidance

| System | Global Interval | UAE Recommendation |

| Engine oil | 10,000 km | 7,000 km |

| Cooling inspection | Visual | Annual pressure test |

| Air filter | 20,000 km | 10,000 km |

| Battery test | 2–3 years | Every 12 months |

| Underbody check | Rare | Annual |

FAQ: “People Also Ask” – HiAce Reliability Questions (2026 Trends)

Why is my 2025–2026 HiAce beeping and showing “Pre-Collision System Unavailable”?

Short answer: the radar is blinded, not broken.

On modern HiAce vans, the forward radar is mounted behind the Toyota emblem. In UAE conditions, fine dust, sand film, or dried mud can block the radar signal and disable the system.

Correct fix

- Clean the front Toyota emblem thoroughly

- Clean the forward camera area at the top of the windshield

- If the warning appeared after windshield replacement, the system requires static ADAS calibration at a certified workshop

Ignoring recalibration causes repeated warnings even when sensors are healthy.

My HiAce idles at 1,200 rpm at traffic lights. Is the engine overheating?

Short answer: no, this is intentional DPF behavior.

On 2019+ HiAce models, the ECU raises idle speed to increase exhaust temperature for passive DPF regeneration.

Technical advice

- Do not shut the engine off while idle is elevated

- If possible, drive above 60 km/h for 15–20 minutes to complete regeneration

- Repeated shutdowns during this cycle accelerate DPF clogging and oil dilution

This behavior is often misdiagnosed as a throttle or cooling fault.

How can I tell if my injector seats are failing before the engine is damaged?

Short answer: injector seal failure makes noise before it makes smoke.

The earliest sign is a rhythmic chuffing or ticking sound that follows engine RPM. This is combustion gas escaping past the copper injector washer.

Pro diagnostic test

- With the engine idling, remove the oil filler cap

- If you feel strong air pulses or see smoke puffs, injector seats are already leaking

Catching this early prevents oil contamination and oil-pickup blockage.

Does DPF failure mean the HiAce engine is unreliable?

Short answer: no, it means the duty cycle is wrong.

Most DPF faults occur on vans used for short, low-speed trips. The engine itself is not failing.

Correct prevention

- Schedule weekly sustained highway driving

- Monitor oil level for fuel dilution

- Use manual regeneration when supported

Fleet data shows DPF-related limp mode drops sharply when regeneration strategy is respected.

Why do HiAce electrical problems appear random?

Short answer: voltage instability triggers multiple systems at once.

Weak batteries, corroded grounds, or heat-soaked relays can trigger starting faults, ADAS warnings, and charging issues simultaneously.

Correct diagnostic order

- Battery load test

- Voltage drop testing under load

- Ground path inspection

- Relay resistance testing

Replacing sensors first usually wastes time and money.

MotorHub UAE connects HiAce owners with workshops experienced in diesel diagnostics, commercial driveline repair, and desert-specific preventive maintenance. In the UAE, correct maintenance is what keeps the HiAce truly unbreakable.